DRYKEEPER

Selection Tool and Guidelines

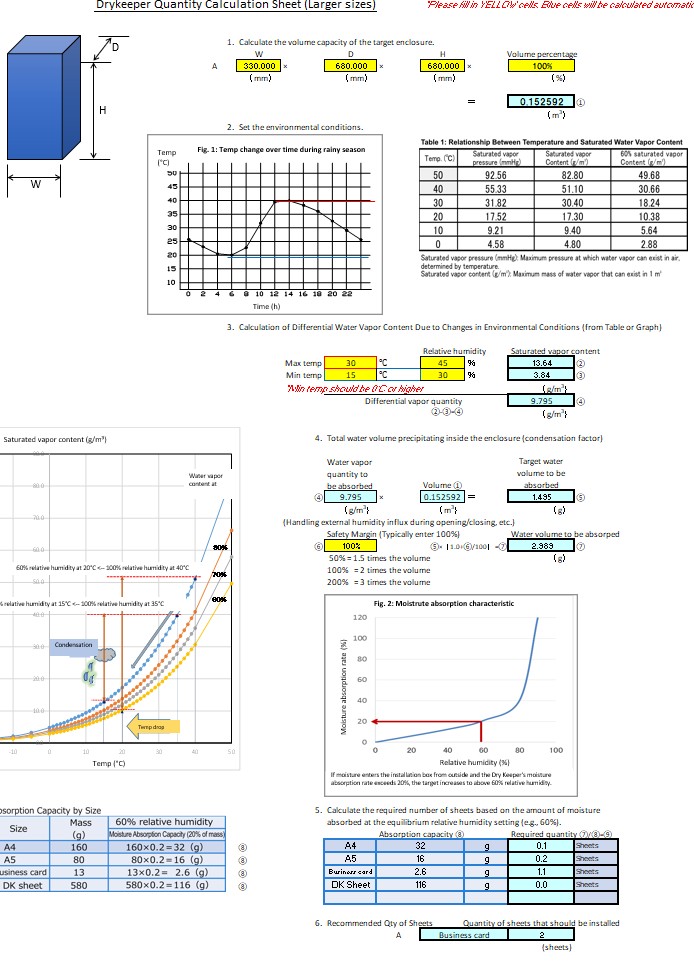

Introduction to the Drykeeper Selection tool.

Here you will find how to select Drykeeper condensation protection products for a range of products from CCTV cameras to outdoor electrical distribution panels. Use this link if you missed the Introduction to Drykeeper condensation prevention products.

Firstly, Drykeeper is not a dehumidifier. It is a condensation buffer for sealed and semi-sealed enclosures and devices. It works without power or maintenance, to stop condensation forming in cabinets and devices. It is ideal for sealed devices and cabinets. For semi-sealed applications, Drykeeper will operate in conjunction with active dehumidifiers like Rosahl ionic membranes.

To control condensation, many engineers focus on relative humidity (RH) alone. While RH is easy to measure and reference, it is the dew point that governs when condensation forms. That is the temperature at which the water vapour present in the air begins to condense on internal surfaces. This distinction is critical when selecting a condensation-prevention solution like Drykeeper.

At the time of sealing a device or enclosure, the absolute humidity (g/m³) inside becomes fixed at the moment of sealing. Once sealed, the total mass of water vapour inside does not change when temperature changes. What changes is the state of that moisture and whether it remains as vapour or condenses into liquid water.

Reversible process

Drykeeper manages condensation by lowering the effective absolute humidity inside the enclosure. It does this by absorbing moisture when the relative humidity is high and releasing it as it falls. Drykeeper stabilises internal humidity in a controlled range, of around 50–60% RH. This long-term reversible absorption–release process follows the natural humidity cycle of the enclosure. By smoothing humidity fluctuations, Drykeeper prevents sharp RH peaks that would otherwise reach the dew point and cause condensation. Drykeeper has an operating life of over 10 years at temperatures ranging from -30° C to +90° C

Drykeeper selection

Because the total moisture load in sealed enclosures is finite, the selection tool calculates the number of Drykeeper sheets. Furthermore, increasing the size or number of the Drykeeper sheets further increases the safety margin (see step 4). This also helps prevent condensation in semi-sealed enclosures.

To calculate the number of Drykeeper sheets needed, we need to know the following:

1 Volume of the target enclosure

2 Maximum expected temperature and humidity

3 Minimum expected temperature and humidity

4 The expected safety factor (150%, 200% or 300%)

With the correct selection, Drykeeper will prevent condensation in sealed non-ventilated enclosures. It achieves this by maintaining an internal relative humidity between 50% and 60%, even when the temperature falls.

Caution: If moisture enters the enclosure from outside, Drykeeper’s moisture absorption may exceed 20%. If so, the target humidity may increase above 60% relative humidity. If this is likely, increase the safety factor as indicated below.

The Drykeeper selection tool use an Excal worksheet that contains no no macros of VBA code. There is a download button at the end of this page.

Image of Drykeeper selection Tool