A Technical White Paper

Condensation in Sealed Enclosures: Causes, Risks, and Prevention

How Dew Point Inside an Enclosure Is Determined

When an enclosure is sealed, the dew point of the trapped air is fixed at that moment. It depends entirely on the temperature and humidity conditions during sealing. For example, if an enclosure is closed on a warm, humid day, the internal dew point will remain high even if the enclosure later cools down.

Key implications:

- Dew point does not change with temperature alone. Cooling the enclosure does not remove moisture; it simply brings surfaces closer to the dew point.

- Condensation risk increases whenever internal surfaces fall below the trapped air’s dew point, even briefly.

- Pressure changes do not remove moisture. Expansion or contraction of the air volume alters pressure, not humidity ratio.

- Moisture introduced during assembly (e.g., from breathing, wet components, or humid ambient air) becomes part of the sealed environment.

Because the dew point is “baked in” at the moment of sealing, controlling humidity before the enclosure is closed—or actively drying the internal air afterward—is essential for preventing condensation.

Executive Summary

Condensation in sealed enclosures remains one of the most persistent and underestimated causes of long-term reliability problems in electrical, electronic, and optical equipment. Engineers frequently trace corrosion, leakage currents, sensor drift, and intermittent faults back to moisture formation inside otherwise well-sealed housings, rather than to component quality or design errors.

This issue is particularly acute in outdoor and remote installations. Daily temperature cycling, solar loading, and night-time cooling repeatedly drive internal conditions across the dew-point threshold. Although the absolute amount of water involved may be very small, the cumulative effect over months or years can significantly shorten service life and reduce system availability.

Drykeeper addresses this challenge by preventing condensation rather than attempting to remove moisture after it has already formed. It operates without electrical power, consumables, or routine maintenance. As a result, it stabilises internal humidity in sealed and non-ventilated enclosures and keeps relative humidity below condensation-forming levels during normal temperature variations.

This white paper explains how condensation forms in sealed enclosures, why traditional mitigation methods often fall short in real-world applications, and where Drykeeper provides a practical, maintenance-free alternative.

Condensation in Sealed Enclosures: a Real-World Problem

In most installations, enclosure condensation does not result from obvious water ingress. Instead, moisture typically enters during manufacture, assembly, installation, or servicing. Once the cabinet is sealed, this moisture becomes trapped inside the enclosure volume.

After installation, ambient temperature changes drive repeated humidity cycles. In outdoor and semi-outdoor environments, these effects are particularly pronounced. During the day, solar heating raises internal air temperature and increases its capacity to hold water vapour. At night, rapid cooling causes relative humidity to rise sharply, often to saturation.

When internal temperatures fall below the dew point, condensation forms on the coldest internal surfaces. These surfaces commonly include metal frames, mounting plates, cable glands, and printed circuit boards. Although each condensation event may be brief and produce only a thin moisture film, the effects accumulate over time.

As a result, corrosion develops, insulation resistance degrades, and long-term reliability suffers. These failures often appear months or years after installation, making root-cause diagnosis difficult. In hard-to-access or safety-critical systems, this delayed failure mechanism can be especially costly.

Understanding Humidity, Relative Humidity, and Dew Point

Humidity terminology often causes confusion. However, a clear understanding of a few key concepts is essential when assessing condensation risk.

Absolute humidity describes the actual amount of water vapour present in the air. Relative humidity indicates how close that air is to saturation at a given temperature. The dew point defines the temperature at which the air becomes fully saturated and condensation begins.

Crucially, relative humidity depends strongly on temperature. Air that appears safe at 50–60 % relative humidity during the day can reach 100 % relative humidity after only a modest temperature drop. Importantly, this occurs even when no additional moisture enters the enclosure.

In compact cabinets, the amount of water required to trigger condensation can be surprisingly small. In many cases, only a few tenths of a gram are sufficient to cause liquid water to form.

Typical Dew Points in Enclosures

The table below illustrates representative dew‑point temperatures for air at common temperature and humidity levels. These values describe the moisture content of the air itself; an enclosure sealed under similar conditions would contain air with a comparable dew point. When any internal surface cools below the corresponding dew‑point temperature, condensation will form.

| Air temperature | Relative humidity | Dew point | Water released |

| 20 °C | 80 % | 10.6 °C | 13.9 g |

| 30 °C | 60 % | 20.3 °C | 20.2 g |

| 40 °C | 50 % | 28.3 °C | 25.5 g |

*Illustrative values only; not a sizing calculation.

Once condensation occurs, even briefly, liquid water can bridge conductors, promote corrosion, and initiate long‑term degradation mechanisms. Preventing the internal environment from reaching saturation is therefore more effective than managing liquid water after it has already formed.

Limitations of Traditional Condensation Control Methods

A range of techniques is commonly used to manage moisture in enclosures. Each approach offers advantages, but each also has limitations.

Desiccant packs are simple and inexpensive. Desiccant materials such as silica gel are widely used because of their simplicity, but in sealed enclosures they are consumable and provide no indication when their moisture-absorbing capacity has been exhausted. Once saturated, they provide no further protection. In sealed outdoor enclosures, their condition is often invisible, which makes maintenance difficult to manage reliably.

Heaters and anti-condensation elements reduce relative humidity by raising internal temperature. While effective in many applications, they require a continuous power supply and introduce ongoing energy consumption. In addition, elevated temperatures can accelerate ageing in temperature-sensitive components.

Ventilation and powered dehumidifiers actively remove moisture. However, they rely on airflow paths that may compromise enclosure sealing or environmental ratings. For remote, battery-powered, or solar-powered systems, power consumption and maintenance requirements can make these approaches impractical.

These established methods work well within their intended contexts. However, they leave a gap for long-life, sealed systems where power availability, access, and routine maintenance are limited.

The Drykeeper Principle

Drykeeper is designed specifically to reduce condensation risk in sealed and non-ventilated enclosures by stabilising internal humidity rather than aggressively removing moisture without electrical power or consumables.

It uses an environmentally friendly maintenance-free polymer absorber with a typical service life of up to 10 years. The sheet buffers internal humidity by absorbing water vapour when relative humidity is high and releasing it when conditions dry, helping to stabilise enclosure humidity in the 50–60% RH range.

It operates as a passive humidity buffer. When relative humidity rises, it absorbs water vapour. When humidity falls, it releases that vapour back into the air. As a result, Drykeeper moderates humidity swings caused by temperature cycling.

By limiting these swings, Drykeeper keeps the internal environment below condensation-forming conditions across normal operating cycles. Importantly, this process requires no electrical power, moving parts, or consumable materials. By reducing the absolute humidity in the enclosure, Drykeeper lowers the dew point, preventing condensation on internal surfaces even as temperatures fall.

Drykeeper does not aim to rapidly dry a wet enclosure. Nor does it replace ventilation or active drying where those approaches are appropriate. Instead, it serves a preventative role by maintaining a stable internal climate and avoiding repeated dew-point crossings.

Drykeeper Compared with Active Dehumidification Methods

Drykeeper occupies a different role from powered dehumidifiers, membrane dryers, and ventilation-based systems. Active solutions remove moisture aggressively and are often used to dry enclosures after installation, wash-down, or ingress events.

However, these approaches rely on electrical power, airflow, or control electronics. As a result, they introduce ongoing energy consumption, additional failure modes, and maintenance requirements.

Drykeeper does not attempt to dry a wet enclosure quickly. Instead, it prevents condensation from forming in the first place. By stabilising internal humidity, it avoids repeated dew-point crossings during normal temperature cycling.

In long-life, sealed systems where moisture ingress is limited and condensation is driven primarily by temperature change, this preventative approach is often more effective. It also avoids the complexity and lifecycle cost associated with powered solutions.

Suitability for Outdoor, Remote, and Energy-Limited Installations

Outdoor, remote, and energy-limited installations impose strict constraints on condensation control strategies. These enclosures often experience wide temperature swings while offering limited access for servicing once deployed.

In many cases, condensation risk arises not from continuous moisture ingress but from trapped moisture combined with daily and seasonal temperature cycling. As a result, even sealed enclosures that remain unopened for years can experience repeated condensation events.

Traditional solutions that rely on electrical power, airflow, or regular maintenance can therefore introduce system-level vulnerabilities. Power availability may be intermittent, and maintenance access may be costly or impractical.

Drykeeper suits these environments because it operates entirely without electrical power. This makes it compatible with solar-powered, battery-powered, and energy-harvesting systems. At the same time, the absence of heaters, fans, or control electronics removes common points of failure.

Equally important is its long, maintenance-free service life. In roadside cabinets, trackside equipment, and remote monitoring stations, even minor maintenance tasks can involve significant logistical or safety challenges. By preventing condensation without intervention, Drykeeper supports long-term reliability and availability.

Installation and Integration in Sealed Enclosures

Drykeeper is designed to integrate easily into sealed and non-ventilated enclosures without altering existing system architecture or environmental ratings.

Because it operates passively, installation does not require wiring, power connections, airflow paths, or control interfaces. In most applications, Drykeeper mounts within the enclosure volume where it can interact with the internal air.

Placement is not critical, provided normal internal air circulation is unobstructed. Unlike active systems, Drykeeper does not require proximity to heat sources, vents, or cable entries.

Good enclosure sealing practice remains important. Uncontrolled air exchange can introduce additional moisture that exceeds intended operating conditions. Where pressure-equalisation elements or breathers are used, their characteristics should be considered as part of the overall moisture management strategy.

Selection is typically based on enclosure volume and expected temperature cycling severity rather than peak moisture loads. This simplifies integration during the design phase and avoids the need for detailed humidity modelling in many cases.

Service Life, Reliability, and Maintenance-Free Operation

Drykeeper is designed to provide long-term condensation prevention over the operational life of the enclosure. It does so without routine maintenance, inspection, or replacement.

Because it operates passively, Drykeeper contains no moving parts, control electronics, or power-related components. This simplicity directly improves system reliability by eliminating common failure modes such as heater burnout, fan failure, or controller malfunction.

In normal sealed-enclosure applications, Drykeeper maintains stable humidity buffering characteristics over many years. Repeated temperature cycling does not diminish its effectiveness, even in demanding outdoor environments.

From a lifecycle perspective, the absence of maintenance requirements reduces total cost of ownership. There is no need to schedule site visits, track consumables, or manage replacement intervals. For large deployments or safety-critical systems, this reduction in operational burden can outweigh initial installation cost.

Typical Applications and Use Cases

Drykeeper is suited to applications where enclosures are sealed or rarely opened and where condensation risk is driven primarily by temperature cycling rather than continuous moisture ingress.

In outdoor electrical cabinets used for traffic control, signage, and roadside infrastructure, internal conditions often fluctuate significantly between day and night. These enclosures are commonly sealed and may be powered intermittently or via solar supplies. Drykeeper provides continuous condensation prevention without increasing power demand or maintenance visits.

Remote monitoring and sensing equipment presents similar challenges. Environmental sensors, data loggers, and communications nodes are often deployed in locations with limited access. Once installed, enclosures may remain closed for years while exposed to seasonal temperature extremes. By stabilising internal humidity, Drykeeper reduces corrosion risk and measurement drift.

Telecommunications and rail applications place a strong emphasis on availability and predictable lifecycle performance. Trackside cabinets and signalling equipment experience repeated thermal cycling while offering little tolerance for unplanned maintenance. Drykeeper supports a fit-and-forget approach aligned with long-term asset management strategies.

Across these applications, the common requirement is stable humidity control over long periods. Drykeeper addresses this requirement by preventing dew-point crossings rather than reacting to liquid water after it forms.

When Drykeeper Is — and Is Not — the Right Solution

Drykeeper is most effective in sealed or rarely opened enclosures where condensation risk is driven primarily by temperature cycling.

In these conditions, preventing relative humidity from reaching saturation is usually sufficient to avoid condensation and its long-term effects. Where enclosures are assembled cleanly and sealed effectively, Drykeeper provides a robust and low-risk solution.

However, Drykeeper is not intended for all moisture-control scenarios. Enclosures that are frequently opened, exposed to direct water ingress, or subject to sustained high moisture loads may require active drying, ventilation, or heating.

Similarly, applications that demand rapid drying after installation, wash-down, or flooding are better served by powered solutions. In some systems, Drykeeper can complement active methods by maintaining stable humidity during normal operation once drying is complete.

Understanding these boundaries allows engineers to apply Drykeeper where it delivers the greatest benefit and avoid unrealistic expectations.

Conclusion: Preventing Condensation at the Source

Condensation remains a subtle but significant threat to the long-term reliability of sealed cabinets and enclosures. In outdoor and infrastructure applications, failures often result from repeated, small condensation events rather than dramatic water ingress.

Traditional mitigation methods typically respond after moisture becomes a problem. While effective in some contexts, they often rely on power, airflow, or maintenance, which may conflict with long-life, sealed system requirements.

Drykeeper takes a different approach. By stabilising internal humidity and preventing dew-point crossings, it addresses condensation at its source. Operating passively and without maintenance, it enables enclosure designs focused on reliability rather than periodic intervention.

For applications where access is limited, power is constrained, and service life expectations are high, condensation prevention is often the more effective strategy.

Call to Action: Technical Evaluation and Support

Engineers, OEMs, and system integrators seeking a maintenance-free approach to condensation prevention in sealed enclosures are encouraged to review the Drykeeper datasheets and selection guidance.

Application support is available to assist with enclosure volume assessment, operating conditions, and integration considerations. Early engagement during the design phase helps ensure effective condensation control throughout the equipment lifecycle.

Further technical information, selection tools, and application examples are available via the Drykeeper product pages or by contacting Westside International for engineering support.

Appendix I; How much water is released?

Absolute Humidity Table (g/m³)

| Air Temp (°C) | 90% RH | 80% RH | 70% RH | 60% RH | 50% RH | 40% RH | 30% RH | 20% RH |

| 40 | 46.0 | 40.9 | 35.8 | 30.6 | 25.5 | 20.4 | 15.3 | 10.2 |

| 35 | 35.9 | 31.9 | 27.9 | 23.9 | 19.9 | 15.9 | 12.0 | 8.0 |

| 30 | 30.3 | 26.9 | 23.6 | 20.2 | 16.9 | 13.5 | 10.1 | 6.7 |

| 25 | 23.0 | 20.4 | 17.9 | 15.3 | 12.8 | 10.2 | 7.7 | 5.1 |

| 20 | 15.6 | 13.9 | 12.2 | 10.4 | 8.7 | 7.0 | 5.2 | 3.5 |

| 15 | 11.5 | 10.2 | 8.9 | 7.7 | 6.4 | 5.1 | 3.8 | 2.6 |

| 10 | 8.5 | 7.6 | 6.6 | 5.7 | 4.7 | 3.8 | 2.8 | 1.9 |

(Rounded to 0.1 g/m³)

From the absolute humidity table, a one cubic metre enclosure at 20 °C and 80 % RH contains approximately 13.9 g of water vapour. If the enclosure is cooled to 15 °C, the air can hold only about 10.2 g/m³ at the same relative humidity. The difference, approximately 3.7 g of water, must therefore condense inside the enclosure. One of the first places condensation becomes noticeable is on internal optical surfaces.

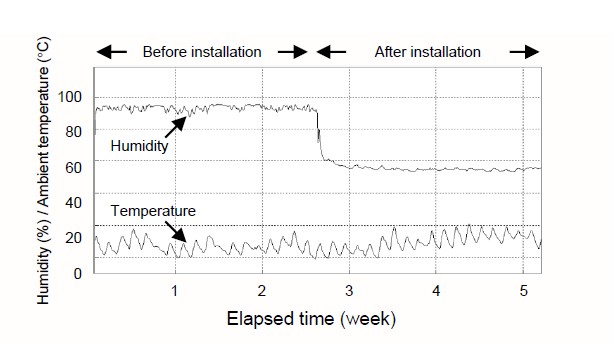

Appendix II; Transition of cabinet humidity before and after installation

of DryKeeper.