Condensation inside electrical cabinets and sealed electronic enclosures is one of the most common—and underestimated—causes of long-term reliability problems. Even small amounts of moisture can lead to corrosion, leakage currents, sensor drift, or intermittent faults that are difficult to diagnose with equipment installed in the field. Cabinet condensation prevention can take various forms.

Silica gel is often the first solution considered. It is inexpensive, widely available, and familiar. However, in cabinets exposed to temperature changes, silica gel does not always provide reliable or lasting protection.

Drykeeper approaches the problem differently. Rather than acting as a consumable desiccant, it provides long-term, maintenance-free humidity control specifically for sealed and non-ventilated enclosures. Because of this fundamentally different operating principle, direct comparisons with silica gel can be misleading.

Why condensation occurs in electronic cabinets

Condensation does not require large amounts of moisture to cause damage. In compact electronic enclosures, only a few tenths of a gram of liquid water can be enough to trigger corrosion, optical degradation, or electrical instability.

The most common cause is temperature change rather than external water ingress. As temperature falls, the air’s capacity to hold moisture decreases and relative humidity rises. When the dew point is reached, water begins to condense—often invisibly at first, forming thin films on metal surfaces, connectors, and circuit boards.

This explains why cabinets can suffer condensation even when they appear dry, sealed, and well protected from the external environment.

Condensation prevention versus moisture removal

Many humidity-control solutions focus on removing as much moisture as possible from an enclosure. While this is essential in some applications, it is not always necessary—and can be counterproductive in sealed systems.

Drykeeper is designed specifically for condensation prevention rather than aggressive drying. Instead of driving relative humidity to very low levels, it stabilises internal humidity below the threshold at which condensation can occur.

By maintaining relative humidity in the range of approximately 50–60% RH, Drykeeper ensures that the dew point is not reached, even during temperature drops. This approach addresses the root cause of condensation without over-drying the enclosure.

How Drykeeper controls humidity in sealed enclosures

Drykeeper operates as a passive humidity buffer rather than an active dehumidifier.

When relative humidity inside the cabinet rises, it absorbs water vapour from the air. When relative humidity falls—typically as temperature increases—it releases that moisture back into the enclosure. This reversible process keeps the internal environment stable and avoids the formation of liquid water.

Because Drykeeper does not expel moisture from the enclosure, the system remains balanced and self-regulating. There are no fans, heaters, power supplies, or control electronics, and no dependency on external conditions.

A maintenance-free alternative to silica gel

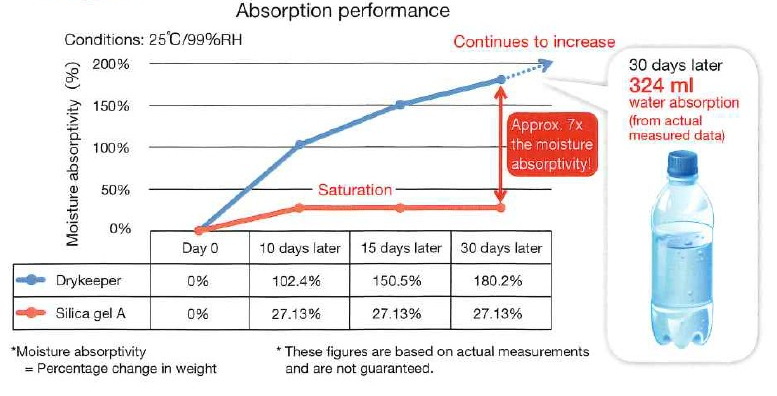

Silica gel absorbs moisture until it becomes saturated. Once full, it no longer provides protection unless it is replaced or regenerated. In enclosures exposed to temperature cycling, this saturation can occur much faster than expected, often without visible warning.

Drykeeper behaves differently. It is not consumed, does not become saturated in normal operation, and requires no servicing or replacement over its typical ten-year service life. This makes it particularly suitable for installations where access is difficult, maintenance intervals are long, or equipment reliability is critical.

Where a passive cabinet dehumidifier makes sense

Drykeeper is well suited to sealed or non-ventilated electrical cabinets, electronic enclosures exposed to temperature cycling, and applications where maintenance-free operation is essential. It is commonly used in long-life equipment where the cost of failure or field servicing far outweighs the cost of the humidity-control solution.

In applications requiring extremely low humidity levels or active moisture removal, alternative technologies may be more appropriate. However, many real-world installations only need to prevent condensation in order to protect sensitive components and ensure long-term reliability.

Choosing the right condensation-prevention method

Condensation damage is often gradual, subtle, and expensive to diagnose after installation. By maintaining relative humidity below the condensation threshold, Drykeeper offers a simple and robust solution for long-term cabinet condensation prevention.

For engineers and OEMs looking for a maintenance-free alternative to silica gel, stabilising humidity—rather than consuming it—can be the most effective approach.

Condensation Control Options Compared

Engineers typically encounter three approaches to condensation control in sealed electrical cabinets: consumable desiccants such as silica gel, cabinet heaters, and passive humidity buffers such as Drykeeper. While all three can reduce condensation risk, they do so in very different ways, with different trade-offs.

Table of Drykeeper vs Silica Gel vs Cabinet Heaters

| Aspect | Drykeeper (Passive Humidity Buffer) | Silica Gel (Consumable Desiccant) | Cabinet Heaters |

| Primary function | Prevents condensation by stabilising RH | Removes moisture until saturated | Prevents condensation by raising temperature |

| Operating principle | Absorbs and releases water vapour reversibly | Absorbs moisture irreversibly | Maintains temperature above dew point |

| Power required | None | None | Yes |

| Maintenance | None (typ. 10-year life) | Replacement or regeneration required | Ongoing power and component checks |

| Behaviour with temperature cycling | Self-regulating and stable | Can saturate quickly | Effective if correctly sized and powered |

| Risk of over-drying | No | Possible | No (but temperature dependent) |

| Performance visibility | Continuous, passive | Protection lost once saturated | Immediate, but power-dependent |

| Best suited to | Sealed, non-ventilated enclosures | Short-term or serviced installations | Powered cabinets with reliable energy supply |

Interpreting the differences

Silica gel is often chosen for its simplicity and low upfront cost. However, it is a finite resource: once saturated, protection is lost unless the desiccant is replaced or regenerated. In enclosures exposed to temperature cycling, this can occur faster than expected and without any obvious indication.

Cabinet heaters address condensation by increasing internal temperature, ensuring the dew point is not reached. This approach can be effective, but it requires a reliable power supply, careful sizing, and ongoing energy consumption. In low-power, remote, or sealed applications, heaters are not always practical.

Drykeeper takes a different approach. Rather than removing moisture or adding heat, it prevents condensation by stabilising relative humidity below the critical threshold. Because the process is reversible and passive, protection is continuous and maintenance-free, making it well suited to sealed enclosures where long-term reliability matters more than aggressive drying.