Features and Installation Guide

Protective Cover and Vapour Transmission Sheet

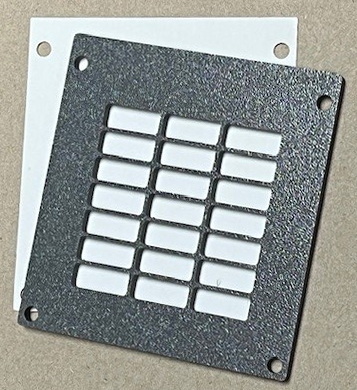

Available for both MDL and M-Series membranes, the VTS protects Rosahl membrane dehumidifiers from water, oil, and dust contamination that could reduce performance. They consist of a moulded grille and a breathable sheet.

Minimising mechanical damage to the membrane during use

The moulded grille also reduces the risk of accidental mechanical damage to the membrane during and after installation, ensuring the integrity and longevity of the membrane under various conditions. Moreover, they hold the protective membrane in place using the membrane fixing holes

Material and Design

Both covers are manufactured from durable mid-grey PETG plastic, chosen for its resilience and suitability for demanding environments. The material ensures that the covers not only protect the membrane but also withstand external conditions without compromising their functionality.

Material and Design

The grille, made from durable mid-grey PETG plastic, provides mechanical protection and is designed for demanding environments. It withstands external conditions without compromising airflow or functionality.

The breathable sheet is a thin PTFE membrane with microscopic pores that allow air and water vapour to pass freely while blocking water droplets, oil mist, dust, and other airborne contaminants. The is membrane is fitted as close to the Rosahl dehumidifier as possible.

Installation is further simplified as the VTS uses the same fixing centres as the membrane dehumidifiers.

Installation Instructions

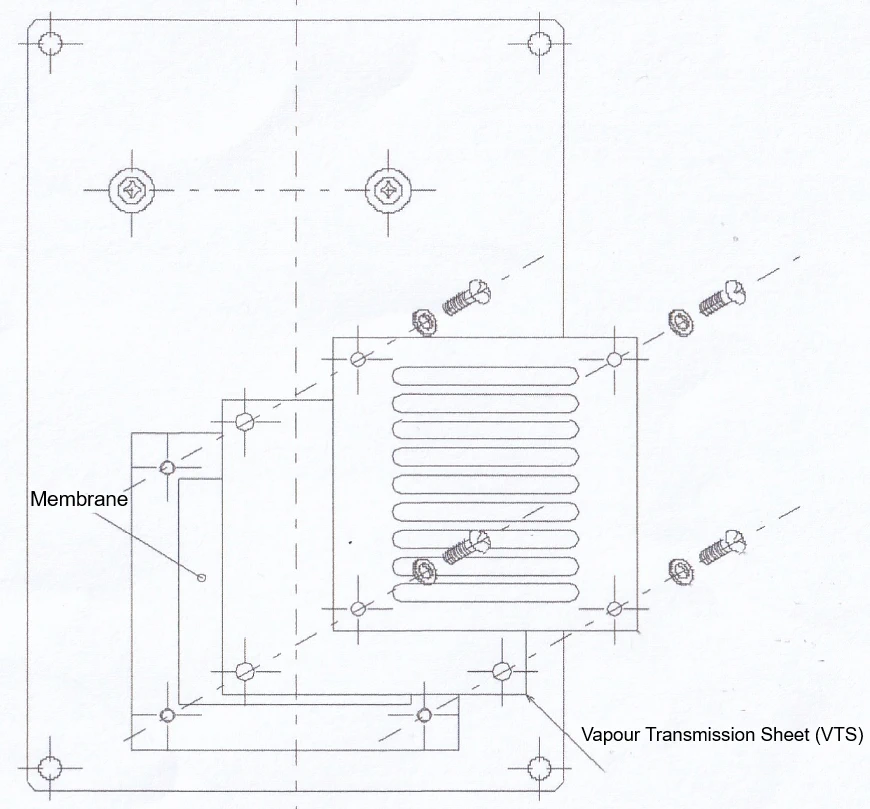

- From the textured (outer) side of the plastic grille, insert two fixing bolts through diagonally opposite mounting holes.

- Place the Vapour Transmission Sheet (VTS) over the bolts, ensuring its smooth surface faces the Rosahl membrane dehumidifier and the textured surface faces outward.

- Position the Rosahl membrane dehumidifier inside the enclosure in the required orientation. Note, some grilles and fixing holes are offset.

- On the outside of the enclosure, align the plastic grille with the bolts, passing them through the case wall and the membrane fixing holes, or when using the MDL models, through the stainless steel mounting plate supplied with the appropriate MDL-*KIT.

- Fit the washers and nuts onto the bolts and hand-tighten to hold the assembly in place.

- Once all components are correctly aligned, insert the remaining bolts and washers and tighten evenly using suitable hand tools—do not overtighten.

Notes

-

- Ensure that the VTS sheet is free from creases or trapped debris before tightening.

- The smooth (inner) side of the VTS must face the membrane to allow correct vapour transmission and protection.

- Do not use power tools when tightening to avoid damage to the plastic grille or membrane.

Tightening torques

| Rosahl membrane | VTS Part No. | Suggested tightening torques |

|---|---|---|

| MDL-3 | MDL3-VTS | 0.30–0.50 Nm (~ 2.65–4.43 lbf·in) |

| MDL-5 | MDL5-VTS | 0.30–0.50 Nm (~ 2.65–4.43 lbf·in) |

| MDL-7 | MDL7-VTS | 0.30–0.50 Nm (~ 2.65–4.43 lbf·in) |

| M-1J1R | M1J-VTS | 0.15–0.20 Nm (~ 1.33–1.77 lbf·in) |

| M-2J1R | M2J-VTS | 0.15–0.20 Nm (~ 1.33–1.77 lbf·in) |

| M-3M1R | M3M-VTS | 0.15–0.20 Nm (~ 1.33–1.77 lbf·in) |

| M-3J1R | M3J-VTS | 0.15–0.20 Nm (~ 1.33–1.77 lbf·in) |

| M-5J1R | M5J-VTS | 0.15–0.20 Nm (~ 1.33–1.77 lbf·in) |

| M-7J1R | M7J-VTS | 0.30–0.50 Nm (~ 2.65–4.43 lbf·in) |

| M-10J1R | M10J-VTS | 0.35–0.60 Nm (~ 3.10–5.31 lbf·in) |

Additional Protective Measures

The VTS and grille plates are compatible with enhanced Rosahl rain covers enhance the overall protection of the membranes in harsh or unpredictable environments.

Westside-International Ltd

Boston House, Downsview Road, Wantage, Oxfordshire, OX12 9FF. UK