CUSTOMER APPLICATION STORY

Maintenance-Free Filament Drying in a Bambu Lab AMS

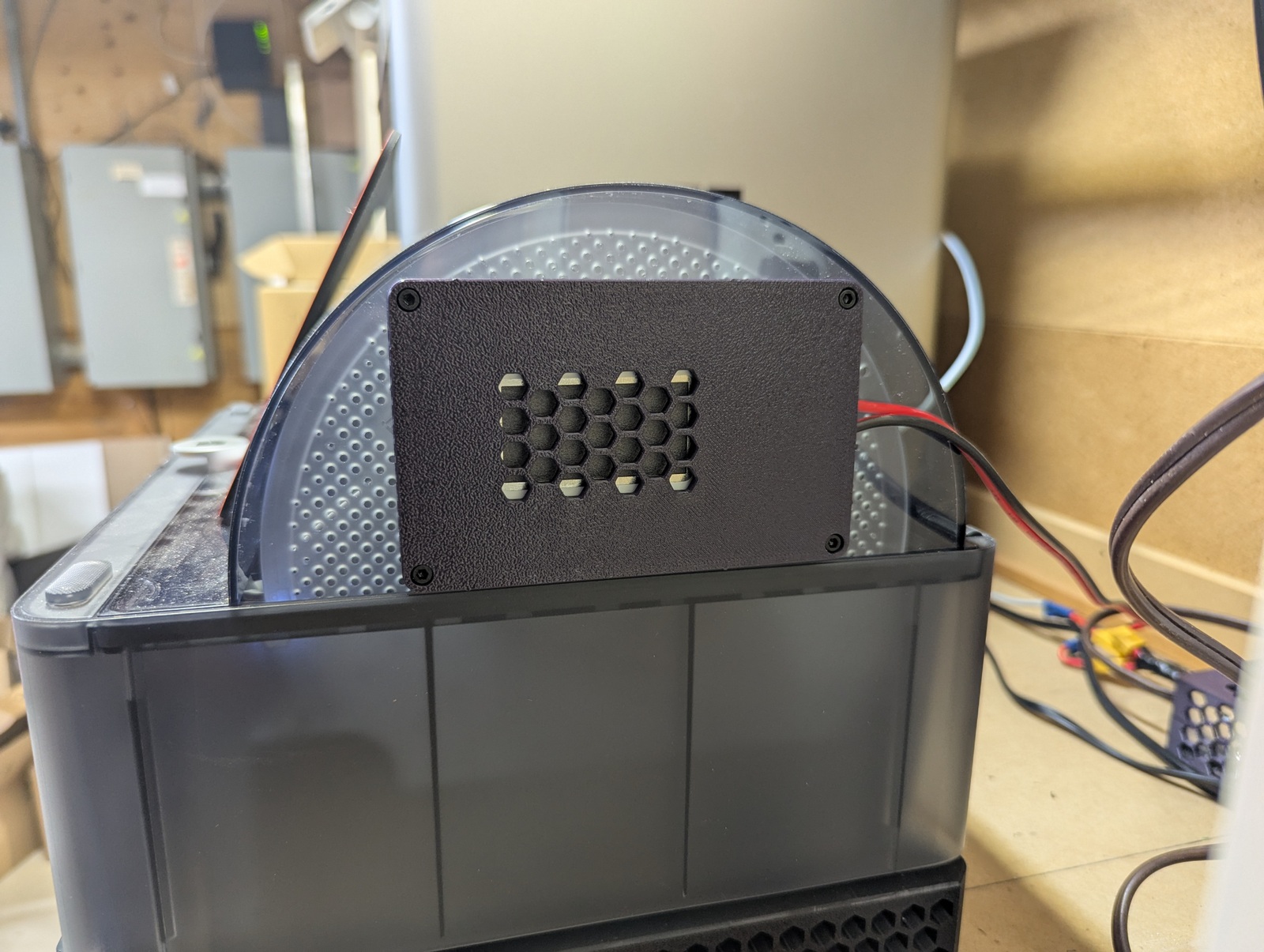

Using a Solid-State Dehumidifier

I’m lazy. Or to be more accurate, I’m lazy about maintenance tasks that need doing periodically. I will spend days or even weeks creating a solution to automate such repetitive tasks even if it’ll be 100× as much effort building that solution than the few minutes here and there I would have spent over the rest of my lifetime doing that maintenance.

When I got my first 3D printer, a Bambu Lab X1C with AMS unit, I knew right away that I would be lax about replacing the desiccant used for filament drying. So when I saw Stefan’s solid-state dehumidifier video on filament drying, I knew what I had to do.

Why I Chose a Solid-State Dehumidifier for Filament Drying

I wanted to learn CAD and the parametric ideas (and price) behind FreeCAD are right in-line with how I think of things. So, I took Stefan’s idea but otherwise started from scratch.

He did mention, at the end of his video, some things he learned, so I tried to correct for those. For example:

- There was very little space between the unit and the last AMS spool: I put the MDL-3 on the outside of the AMS.

- With a full AMS and no use, there is little air movement: I made use of that extra space inside to add a small fan.

Air Circulation Inside the AMS

I chose a 12 V, 0.1 A brushless blower fan (40 × 40 × 10 mm). Powering that fan off the same supply as the MDL-3 means it runs slow (about one-quarter speed), but it’s enough to move the air around inside the AMS over the timeframes we’re interested in here.

Long-Term Results

This setup has been running well for over a year. The hygrometer inside the AMS shows around 11 % relative humidity, even when it is over 50 % RH in my basement.

The old Bambu firmware showed a consistent “1” for humidity and the newer firmware has ranged between 7 % and 9 %. Overall, the results have been excellent.

Filament gives up water even without heating if the surrounding air is drier. This solution dries filament slowly but continuously and, more importantly, prevents moisture uptake in the first place.

Design Overview

There are four parts to the design:

- The outside enclosure, which holds the MDL-3 with space for wiring

- The inside enclosure, with space for a friction-fit blower fan (a thinner version is available if no fan is used)

- A drilling and cutting template for positioning on the AMS cover

- A soft TPU gasket to seal the MDL-3 and keep the AMS relatively air-tight

Materials and Printing

I printed the first three parts in PETG for better impact resistance than PLA. I printed it in purple PETG because I didn’t look closely when ordering and thought it was black. Oops.

There are a few small supports to remove from the bolt holes and wiring slot. This was my first large CAD project, so I’m sure there are cleaner ways to do it.

Assembly Instructions

- Do a full dry run before drilling or cutting

- Tape the template to the AMS cover, centred with the main hole toward the front

- Drill four 3.5 mm corner holes

- Mark and cut the opening using a Dremel or similar tool

- Drill an additional small hole for fan wiring if using the blower

- Insert four M3 hex nuts into the inside enclosure

- Fit the MDL-3 into the outside enclosure and connect wiring (the positive terminal must face the AMS)

- Fit the gasket and lightly tighten the M3 bolts

- Confirm the fan runs and the membrane warms

- Fully tighten all bolts

That’s it. You never need desiccant again.

How the MDL-3 Solid-State Dehumidifier Works

These units work using electrolysis. Water molecules contacting the membrane are split, with hydrogen transported to the outside and released as water vapour. The resulting increase in oxygen concentration inside the enclosure is negligible.

The units run at approximately 3 V and are not inherently current-limited. If moisture accumulates on the membrane during unpowered periods, the unit can attempt to draw excess current at startup.

Power Supply Considerations

For reliable operation, the MDL-3 requires a current-limited power supply. Standard supplies may shut down instead of limiting current, preventing the membrane from clearing accumulated moisture.

Current-limited supplies reduce voltage temporarily until normal operation resumes. A suitable regulator was used in this installation.

Product Selection Notes

I selected the MDL-3 size membrane because it offered good performance margin. Smaller membranes would work but with slower drying performance.

If building again, I would likely use a complete module solution with a robust regulator connected directly to the AMS 24 V supply.

Original Project Source

This application story was first published on Makerworld and is reproduced here with permission of the author.

MDL-3 Solid State Dehumidifier for AMS – Free 3D Print Model – MakerWorld